Air-Cooled Heat Exchangers

Custom Air-Cooled Heat Exchanger Design and Fabrication for Your Needs

At Exchanger Industries Limited, we have designed and fabricated air-cooled heat exchangers – otherwise known as aerial coolers – in forced draft, induced draft and natural convection varieties for clients worldwide.

With a full team of highly experienced thermal and mechanical design experts on staff, our engineering department can take on your most complex heat exchanger design challenge.

Our Solutions

From the bitter cold of the Arctic to the scorching deserts of the Middle East, we deliver equipment solutions worldwide that meet and exceed our customers’ performance expectations.

Our aerial coolers can include either box, cover plate or billet headers for a wide range of services. Our engineers design all systems to API Standard 661 with winterization where required, and our industrial cooling expertise extends to designs for marine and tropical environments as well.

While designing equipment to withstand even the harshest conditions, we collaborate with customers to carefully balance capital and operating expense considerations to minimize product life cycle costs.

Exchanger Industries offers complete support in the design, fabrication and lifecycle of air-cooled heat exchangers and we also provide aftermarket services for maintenance and parts. Our team is ASME U, S, R and NB certified, we meet API and relevant industry standards, and have global supply chain flexibility and in-house expertise to tailor our products to your specifications and requirements.

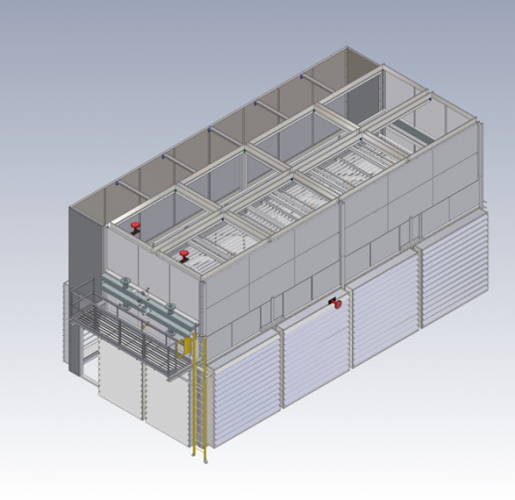

Forced Draft Air-Cooled Heat Exchangers

In a forced draft air-cooled exchanger, fans are set below the tube bundles and push air across the tube surface. This design allows for better accessibility for maintenance and fan blade adjustment. As a result, it needs less structural support, it can have a longer mechanical life and it can lower the capital costs.

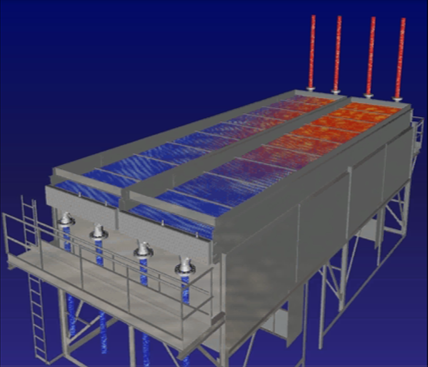

Induced draft air-cooled heat exchangers

Induced draft air-cooled exchangers have fans located above the bundle and air is pulled across the finned tube surface. This arrangement provides a more even distribution of air due to lower air velocity. Additionally, an induced draft air-cooled exchanger is less likely to recirculate exhaust air and is less susceptible to sudden temperature changes since only a portion of its surface is exposed to the elements.

Natural draft air-cooled heat exchangers

Natural draft air-cooled exchangers operate the way their name suggests: there are no fans to push or pull air through the tube bundle. Instead, a chimney above the tube bundle creates the draft that drives air through the tube bundle.

Specifications at a Glance

HEADER TYPES

- Header box/plug

- Cover plate

- Billet

MATERIALS

- Carbon steel

- Low Alloy (1.25 Cr, 2 Cr, 5 Cr, 9 Cr, 13 Cr)

- Austenitic 300 series stainless (304, 316, 317, 321, etc)

- Duplex stainless steels

- High alloy (600, 800, 825 series)

- Weld overlay (300 series, high-alloy)

PRESSURES

- Atmospheric up to 6,000 PSIG (welding up to 3 inches thick)

SIZE

- Width – 26 feet

- Length – 70 feet

- Weight – 20,000 lbs to 150,000 lbs

DESIGN

- T.R.I. – Category III member

- Aspentech TEAMS, Compress

- FE/Pipe and Nozzle/Pro

- Customized software

- AutoCAD, Inventor

- FEA – ANSYS (sub-contracted)