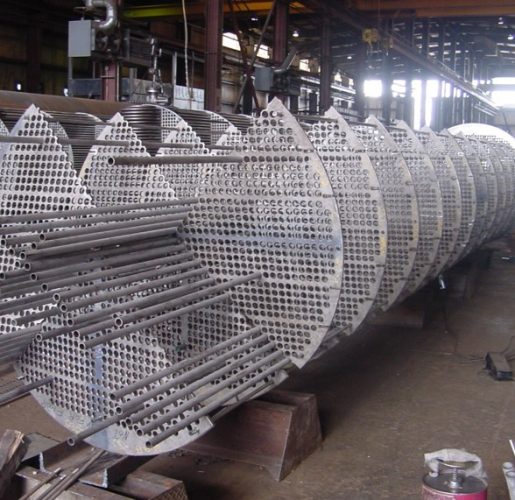

SHELL AND TUBE EXCHANGERS

Custom Heat Transfer Solutions

Exchanger Industries Limited has been a leader in custom shell & tube heat transfer solutions since 1961. With headquarters and Canadian manufacturing located in Calgary, Exchanger Industries has long-standing relationships with manufacturers in India, Korea, China and the U.S. that allow us to provide our clients with a broad range of delivery and pricing options to meet their exact needs.

Exchanger Industries’ shell and tube heat exchangers are used by an extensive selection of blue-chip international companies operating in the natural gas, petrochemical and oil industries. Our extensive experience with carbon steel, high alloys and weld overlay materials allows us to meet a wide variety of shell and tube heat exchanger design requirements including finned tube heat exchangers.

TEMA & API 660

Our experienced engineering and product design teams have the procedures necessary to ensure compliance with both industry-wide standards; TEMA and API 660. Exchanger Industries is ASME certified including U, S and R stamps and we follow the Audited Quality Program.

EMbaffle®

At Exchanger Industries, we take pride in being heat transfer experts and leveraging best available technologies (BAT) for the benefit of our clients. EMbaffle® is one such technology that has delivered tangible savings to numerous customers via improved heat transfer and reduced shell-side fouling.

Exchanger Industries is one of three global licensees – and the only North American licensee – approved to manufacture EMbaffle® products. EMbaffle® represents a step change within tube support baffle design with significant performance benefits compared to conventional designs. It can successfully be added to both new projects and refurbishments.

CHANGING THE SHAPE OF BAFFLE DESIGNS

The pioneering EMbaffle® design features an expanded metal (EM) baffle grid made of plate material that has been slit and expanded. The design reduces fouling, eliminates vibration and can be made more compact than a traditional baffle design through reduced diametrical dimensions and weight. The result is a major improvement in heat exchanger performance, leading to better heat transfer, reduced energy consumption and lower CO2 and NOX emissions. Add it all up and you can materially reduce operating costs.

The EMbaffle® design effectively eliminates tube vibration along with the associated risk of systems mechanical damage. This absence of cross-flow induced vibration allows considerable flexibility in heat exchanger design.

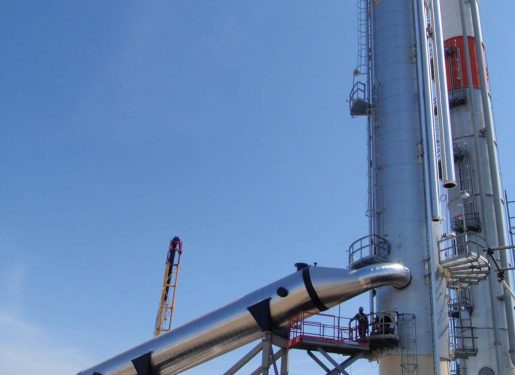

HELIXCHANGER® heat exchangers increase capacity and lower maintenance costs for existing plants as well as reducing capital investment, plot space and energy costs for grassroots applications. More than 5,000 HELIXCHANGER® heat exchangers are in operation worldwide throughout the oil and gas, refining, petrochemical and chemical industries.

Exchanger Industries has designed and manufactured more than 300 HELIXCHANGERS® since beginning our partnership with Lummus Technology in 2004. With its double helix designs, 40-degree helix angles and up to 76-inch diameter, the HELIXCHANGER® provides you with an improved shell side heat exchanger transfer and reduced fouling.

HELIXCHANGER® applications include crude pre-heat exchangers, feed preheat exchangers in delayed cokers, feed/effluent exchangers in refinery and petrochemical processes, bitumen exchangers in oil-sands, major system equipment in ethylene plants and polymer solution coolers in the chemical industry.

ADVANTAGES

When compared with conventional, perpendicular, segmentally baffled shell and tube heat exchangers, HELIXCHANGER® heat exchangers offer several advantages:

- Enhanced heat transfer

- Lower shell-side pressure drops

- Capital cost savings – typically 20%

- Lower shell-side fouling

- Extended run-length and service life

- Reduced vibration hazards

- Reduced heating, pumping and maintenance costs

- Increased process capacity of up to 40%