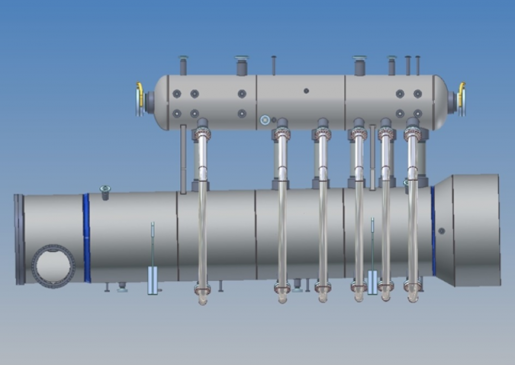

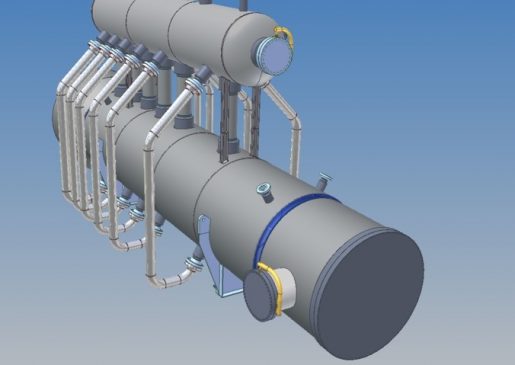

Waste Heat Boilers & Sulphur Condensers

Industry-Leading Thermal Design for Waste Heat Boilers and Sulphur Recovery Units

Why Consider a Waste Heat Boiler?

A waste heat boiler captures byproduct heat from other processes and uses it to create steam. The steam can promote thermal integration by heating other fluids or drive electricity-producing turbines.

Waste heat boilers offer an effective means of recycling thermal energy, and – since byproduct heat is often lost to the atmosphere – this translates directly into reduced fuel consumption, lower GHG emissions and improved overall system efficiency. All of which contribute to lowering your operating costs.

Deep Experience With Critical Thermal Design Equipment

Exchanger Industries Limited is among the few manufacturers with decades of experience in designing and fabricating these complex pieces of equipment. We leverage our proprietary thermal design software, 3D parametric models, CFD and FEA analysis, and specialized manufacturing methods to provide every waste heat boiler with the due diligence it deserves given its critical nature, including expertise with:

- Inner-bore tube-to-tubesheet joints

- thermosiphon cooling design, and

- steam separation internals

In some systems, like Sulphur Recovery Units (SRUs), waste heat boilers are considered the “weak link”; however, Exchanger Industries has manufactured waste heat boilers that have been in service for over 20 years without needing replacement or extensive maintenance. This level of performance is a testament to our focus on engineering and reliability and highlights the value we are proud to bring to the industry.

Your Sulphur Recovery Partner

Exchanger Industries is a technological and fabrication one-stop-shop with the highest industry design and fabrication standards coupled with over 50 years of successful greenfield installs and brownfield retrofits. We align specification requirements and execution efficiency while reducing interface points and client management costs.

Besides providing you all the heat transfer requirements in an AGR (acid gas recovery) unit, Exchanger Industries has developed the specialized capability to provide turnkey equipment packages as part of completing your Sulphur recovery unit. The SRU receives the H2S-bearing streams from the AGR and recovers H2S as elemental sulphur through the Claus reaction.

In addition to our core expertise in waste heat boilers, steam drums and sulphur condensers, we provide:

- State of the art high efficiency burners customized to your application with our industry partner HEC

- Reaction Furnaces

- Valve Train

- Re-heaters

- TGT