About Exchanger Industries

A REPUTATION FOR QUALITY & INTEGRITY

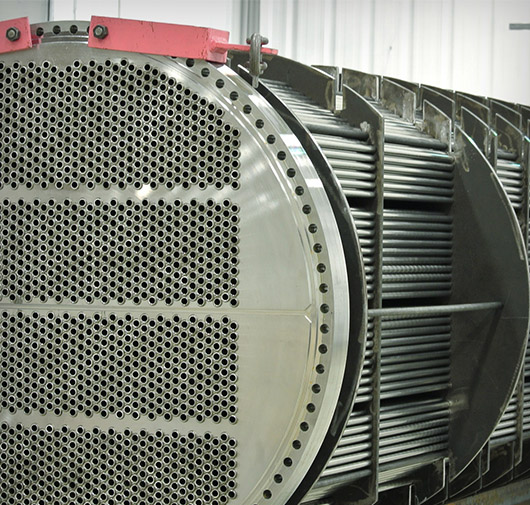

Since our founding in 1961, Exchanger Industries has built a reputation as a leading Alberta-based and globally recognized designer and manufacturer of shell & tube and air-cooled heat exchangers within the natural gas, oil and petrochemical industries.

We are known by our clients for superior execution, unwavering product quality and a relentless focus on improving customer project profitability. Today, we are committed to building on our 60-year track record of delivering custom heat transfer solutions that increase efficiency and reduce costs.

Our international customer base ranges from Fortune 500 oil & gas companies to cutting-edge renewable energy start-ups, and they all rely on our unmatched industry experience to deliver cost-effective, innovative solutions for even the most difficult heat transfer problems.

In 2021, EIL completed the acquisition of HRS Heat Exchangers, the widely recognized preeminent international specialist supplier of heat exchangers and custom process systems across the environmental, food, beverage, and pharmaceutical sectors. The acquisition accelerated EIL’s expansion into renewable industries and provided access to established but still rapidly expanding geographic markets in the U.S., U.K., Spain, Mexico, India, Malaysia, Australia, and New Zealand. In addition, the combined manufacturing capability and leading-edge product technologies of both companies will strengthen EIL’s differentiated value proposition and increase market penetration internationally.

ABOUT HRS HEAT EXCHANGERS

Founded in 1981, the HRS Group operates at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide with a strong focus on managing energy efficiently. The company offers plate heat exchangers, corrugated tube heat exchangers (annular space heat exchangers, double tube heat exchangers, multitube heat exchangers) and scraped surface heat exchangers. HRS products and systems are used in HEVAC, food processing, chemical, pharmaceutical, water and energy industries, waste management and environmental protection. In 2019, HRS was ranked number 161 in the U.K.’s prestigious International Track 200 League Table. For more information, visit https://www.hrs-heatexchangers.com/.

OUR DIFFERENCE

Since 1961, Exchanger Industries has forged strong, long-lasting relationships by effectively meeting our customers’ needs for complete solutions that maximize full project life-cycle profitability. We do this by leveraging best-in-class engineering, design, supply chain and project management expertise to ensure our high standards are maintained from planning through delivery.

Though Exchanger Industries has called Alberta, Canada home since its founding in 1961, in the last decade, we have integrated a global supply chain of rigorously qualified heat exchanger manufacturing facilities so that our customers receive the highest quality products at competitive prices.

Over six decades, we’ve gathered welding expertise and an extensive exotic alloy weld procedure library that allows us to tackle jobs that many other suppliers and manufacturers of heat transfer systems simply cannot.

Exchanger Industries continues to qualify and implement the newest, leading-edge enterprise systems to maximize value for our customers. Customized 3-D CAD, Enterprise Resource Planning (ERP), Material Resource Planning (MRP), and proprietary activity cost-based estimate programs build the foundation for efficient scalability that allows us to further improve cost competitiveness while maintaining the integrity and quality that our customers demand. EIL’s upgraded competitive capabilities resulting from these operational effectiveness initiatives have driven increases in relative market share in rapidly growing natural gas midstream, natural gas power generation, liquefied natural gas, petrochemical and renewable powers storage end use segments.

EIL is the co-developer and exclusive licensee of a breakthrough coating product that can mitigate high-temperature fouling of heat exchanger tubes and save customers millions of dollars in maintenance and downtime costs – the company estimates the coating has a market potential of $100 million in Western Canada alone.

To build the globally recognized leader in the field of custom heat transfer. EIL is trusted by its customers to leverage over 60 years of experience working in the world’s toughest operating conditions, to design and manufacture innovative custom heat transfer solutions that reduce customers’ energy consumption, cut costs and reduce their environmental impact. EIL is committed to drive improved customer project profitability, on-time, every time.

Our roots are grounded in the technically challenging conditions of the oil fields of Alberta, but our customer base, our track record of projects, and our supplier network spans the globe and looks to the future in supporting the rapid emergence of alternative energy projects in our key strategic markets in Canada, the U.S. and the Middle East. Our international customer base ranges from Fortune 500 multinationals to cutting-edge renewable energy start-ups.

We are known by our clients for superior execution, unwavering product quality and a relentless focus on improving project profitability. We do this by leveraging best-in-class engineering, design, supply chain and project management expertise to ensure our high standards are maintained from planning through delivery.

EIL Strategy

Exchanger Industries Limited (EIL) is an Alberta-based, globally recognized leader in the provision of innovative, quality, custom heat transfer equipment, services and differentiated solutions that allow our customers to exceed their objectives for both project life cycle and product life cycle profitability. EIL fulfills this promise by:

- Combining over 150 years of cumulative in-house engineering and design experience, with 60 years of exposure to the widest possible range of applications and product solutions to develop, to date, over 11,000 integrated, innovative, custom heat transfer solutions. Often, we can find solutions to difficult problems that others cannot.

- Qualifying and rigorously training, over the last decade, an array of high quality, proven, international supply chain partners to provide our clients with a range of price to delivery lead time options that best suit their needs.

- Leveraging the latest in streamlined and automated business processes and enterprise-level software to eliminate waste and deliver defect-free product, on-time, every time.

- Offering a range of core heat transfer products and after-sales services, each supported by decades of experience. This allows us to act as a ‘One-Stop-Shop’ for our customers, minimizing procurement costs and streamlining project execution.

- Standing behind our products for their full life cycle by providing complete aftermarket service for maintenance and parts.

- Developing a portfolio of cutting-edge heat transfer technologies that will, based on driving down total operational costs, help differentiate our heat exchanger solutions.

- Utilizing the HRS acquisition as a vehicle for accelerating our growth internationally, and enhancing our differentiated position via an improved range of antifouling solutions, a highly experienced management team and access to additional cost-effective and scalable manufacturing hubs.

From our headquarters in Calgary, we serve a variety of customer segments defined by industry vertical and geographic location for both new build (greenfield) and replacement or maintenance (brownfield) projects. Within these core segments, we have delivered products across Alberta and worldwide to the most recognized and prestigious Fortune 1000 energy and chemical companies for applications including:

NATURAL GAS MIDSTREAM NGL AND LNG

For compression in natural gas pipelines, as well for Natural Gas Liquids (NGL) and Liquefied Natural Gas (LNG) installations, Exchanger Industries holds a market-leading position in the Western Canadian Sedimentary Basin (WCSB).

CLEAN POWER GENERATION

EIL, as one of the North American leaders in the design and fabrication of air-cooled heat exchangers, is taking on an important role in:

- Facilitating the ongoing transition from coal-fired power to high-efficiency, low emission combined cycle natural gas-fired generating facilities.

- Collaborating with some of the world’s leading engineering firms to install facilities that will capture waste heat from a gas-fired turbine operating at a pipeline compression station and convert it into emissions-free power.

- Supplying to the geothermal power market, which is experiencing rapid growth recently, given its carbon-free and renewable characteristics. EIL has significant expertise in the application of air coolers in geothermal, in combination with our antifouling coatings technologies, to combat the severe silicate scaling that often acts to lower operational efficiency and increase maintenance costs.

BIOFUELS

Biofuels refers to the specific type of fuel derived from a wide source of feedstocks such as plants, organic materials, landfill, wood and animal wastes. The biofuel industry is gaining substantial investment momentum as an attractive, alternative source of low carbon, low sulphur alternative to fossil fuels. EIL has a unique set of capabilities that will act in combination to allow us to provide differentiated, and in some cases unique, solutions to the biofuels market, including:

- Our 60 years of experience designing waste heat boilers gives us considerable insight into providing heat exchangers and boilers that will operate efficiently and reliably in continuous use at extreme temperatures exceeding 2,000°F.

- Our automated CAD design service allows EIL to minimize the complexity (extra design and customer review lead time) associated with the large number of designs for heat transfer solutions often required in biofuel facilities.

- Our antifouling coating technologies can operate effectively in the high-temperature environments required in biofuel processes and act to eliminate the downtime and high maintenance costs of the fouling created by certain types of feedstock, including wood waste, landfill garbage and non-recyclable plastics.

- Our long history of successfully developing innovative custom heat transfer solutions is particularly important for end-use applications such as biofuels, which do not yet have standardized heat transfer packages.

RENEWABLE POWER STORAGE

As the global energy grid decarbonizes, the rapid transition to new power sources and the simultaneous decommission of high carbon traditional baseload power sources (coal) have resulted in increased intermittency in the provision of reliable, cost-effective electricity. As a result, the energy market is under pressure to provide affordable, scalable solutions that can store energy for many hours – even days. Leading power storage solutions using compressed air create unique stresses on traditional heat exchanger designs. EIL is the only heat exchanger fabricator in the world to have collaborated closely on HEX design with the pioneers in this industry and can claim to have a full-scale installed base in the field. This invaluable experience positions EIL to become a worldwide leader in this rapidly growing segment.

PETROCHEMICAL

Exchanger Industries holds a market-leading position for this rapidly growing vertical in

Alberta, but also supplies to projects in the U.S. Gulf Coast (USGC) as well as the Middle East

and Asia. This includes primarily greenfield applications for oil and gas refineries as well as

plants that convert NLGs to various end products such as polypropylene and methanol.

UPSTREAM ALBERTA OIL

Our roots are grounded in the challenging operating conditions of the oil fields of Northern Alberta. More than ever, our valued Alberta oil customers need solutions to minimize total life cycle product costs as well as energy use. Exchanger Industries supplies products for both greenfield and brownfield applications, and we have the largest installed base of heat exchangers for oil extraction and refining in the Western Canadian Sedimentary Basin. Going forward, further growth in the brownfield segment is expected to maintain and replace the installed base to, in turn, drive increased operational efficiencies.

ANTIFOULING

Fouling is generally defined as the deposition and accumulation of unwanted materials such as scale, algae, suspended solids and insoluble salts on the internal or external surfaces of processing equipment, including boilers and heat exchangers. Fouling on process equipment surfaces can have a significant, negative impact on the unit’s operational efficiency.

- Total fouling-related costs for major industrialized nations are estimated to exceed US$5.5 billion annually.

- Other estimates calculate the losses due to fouling of heat exchangers in industrialized nations to be about 0.25% to 30% of their GDP.

- About 10% of the total maintenance costs of a process plant can be attributed to the fouling of heat exchangers and boilers.

In partnership with a leading global chemical company, EIL has developed, piloted, and commercialized a proprietary coating for heat exchanger components. This premium product combats clogging or “fouling” in units which typically require significant cleaning costs and downtime. This revolutionary solution will have applications across all our industry verticals and geographies and will reinvent the economics of many industrial processes.

Our Values

We’ve learned a few things over the last 60 years, including who we are and how to treat customers right. Our values act as the foundation for everything we do and guide us as we learn, adapt and evolve in always-shifting markets.

- Safety Above All:

Our goal is Zero.

Zero lost-time accidents.

Zero recordable injuries. - Understanding and Value Your Colleagues: By building trust and improving teamwork, we can ably rely on one another to ensure that we have challenging careers with opportunities to grow personally and professionally.

- Fail Forward:Growth and improvement require people to take on new responsibilities and calculated risks. Mistakes, in this context, will always be understood. Make decisions, stand by those decisions, and learn from mistakes.

FORCED/CHILD LABOUR ANNUAL REPORT

EIL has a zero-tolerance approach to forced labour and child labour, as well as any other forms of modern slavery. We are committed to acting ethically and with integrity and transparency in all business dealings, and to maintaining systems and controls to safeguard against any form of forced labour, child labour or modern slavery taking place within our business or our supply chains.

We demand the same attitude of all who work for us and expect it of all with whom we have business dealings.